What is LED?

The LED is a specialised form of PN junction that uses a compound junction. The semiconductor material used for the junction must be a compound semiconductor. The commonly used semiconductor materials including silicon and germanium are simple elements and junction made from these materials do not emit light. Instead compound semiconductors including gallium arsenide, gallium phosphide and indium phosphide are compound semiconductors and junctions made from these materials do emit light.

The LED is a specialised form of PN junction that uses a compound junction. The semiconductor material used for the junction must be a compound semiconductor. The commonly used semiconductor materials including silicon and germanium are simple elements and junction made from these materials do not emit light. Instead compound semiconductors including gallium arsenide, gallium phosphide and indium phosphide are compound semiconductors and junctions made from these materials do emit light.

A “Light Emitting Diode” or LED as it is more commonly called, is basically just a specialised type of PN junction diode, made from a very thin layer of fairly heavily doped semiconductor material.

When the diode is forward biased, electrons from the semiconductors conduction band recombine with holes from the valence band releasing sufficient energy to produce photons which emit a monochromatic (single colour) of light. Because of this thin layer a reasonable number of these photons can leave the junction and radiate away producing a coloured light output.

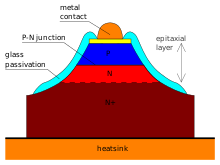

LED Construction

Then we can say that when operated in a forward biased direction Light Emitting Diodes are semiconductor devices that convert electrical energy into light energy.

The construction of a Light Emitting Diode

is very different from that of a normal signal diode. The PN junction of an LED is surrounded by a transparent, hard plastic epoxy resin hemispherical shaped shell or body which protects the LED from both vibration and shock.

Surprisingly, an LED junction does not actually emit that much light so the epoxy resin body is constructed in such a way that the photons of light emitted by the junction are reflected away from the surrounding substrate base to which the diode is attached and are focused upwards through the domed top of the LED, which itself acts like a lens concentrating the amount of light. This is why the emitted light appears to be brightest at the top of the LED.

However, not all LEDs are made with a hemispherical shaped dome for their epoxy shell. Some indication LEDs have a rectangular or cylindrical shaped construction that has a flat surface on top or their body is shaped into a bar or arrow. Also, nearly all LEDs have their cathode, ( K ) terminal identified by either a notch or flat spot on the body, or by one of the leads being shorter than the other, ( the Anode, A ).

Unlike normal incandescent lamps and bulbs which generate large amounts of heat when illuminated, the light emitting diode produces a “cold” generation of light which leads to high efficiencies than the normal “light bulb” because most of the generated energy radiates away within the visible spectrum. Because LEDs are solid-state devices, they can be extremely small and durable and provide much longer lamp life than normal light sources.

LED operation

The LED is a specialised form of PN junction that uses a compound junction. The semiconductor material used for the junction must be a compound semiconductor. The commonly used semiconductor materials including silicon and germanium are simple elements and junction made from these materials do not emit light. Instead compound semiconductors including gallium arsenide, gallium phosphide and indium phosphide are compound semiconductors and junctions made from these materials do emit light.

The LED is a specialised form of PN junction that uses a compound junction. The semiconductor material used for the junction must be a compound semiconductor. The commonly used semiconductor materials including silicon and germanium are simple elements and junction made from these materials do not emit light. Instead compound semiconductors including gallium arsenide, gallium phosphide and indium phosphide are compound semiconductors and junctions made from these materials do emit light.

These compound semiconductors are classified by the valence bands their constituents occupy. For gallium arsenide, gallium has a valency of three and arsenic a valency of five and this is what is termed a group III-V semiconductor and there are a number of other semiconductors that fit this category. It is also possible to have semiconductors that are formed from group III-V materials.

The diode emits light when it is forward biased. When a voltage is applied across the junction to make it forward biased, current flows as in the case of any PN junction. Holes from the p-type region and electrons from the n-type region enter the junction and recombine like a normal diode to enable the current to flow. When this occurs energy is released, some of which is in the form of light photons.

It is found that the majority of the light is produced from the area of the junction nearer to the P-type region. As a result the design of the diodes is made such that this area is kept as close to the surface of the device as possible to ensure that the minimum amount of light is absorbed in the structure.

To produce light which can be seen the junction must be optimised and the correct materials must be chosen. Pure gallium arsenide releases energy in the infra read portion of the spectrum. To bring the light emission into the visible red end of the spectrum aluminium is added to the semiconductor to give aluminium gallium arsenide (AlGaAs). Phosphorus can also be added to give red light. For other colours other materials are used. For example galium phoshide gives green light and aluminium indium gallium phosphide is used for yellow and orange light. Most LEDs are based on gallium semiconductors.

Light Emitting Diode Colours

So how does a light emitting diode get its colour. Unlike normal signal diodes which are made for detection or power rectification, and which are made from either Germanium or Silicon semiconductor materials, Light Emitting Diodes are made from exotic semiconductor compounds such as Gallium Arsenide (GaAs), Gallium Phosphide (GaP), Gallium Arsenide Phosphide (GaAsP), Silicon Carbide (SiC) or Gallium Indium Nitride (GaInN) all mixed together at different ratios to produce a distinct wavelength of colour.

Different LED compounds emit light in specific regions of the visible light spectrum and therefore produce different intensity levels. The exact choice of the semiconductor material used will determine the overall wavelength of the photon light emissions and therefore the resulting colour of the light emitted.

Light Emitting Diode Colours

| Typical LED Characteristics | |||

| Semiconductor Material | Wavelength | Colour | VF @ 20mA |

| GaAs | 850-940nm | Infra-Red | 1.2v |

| GaAsP | 630-660nm | Red | 1.8v |

| GaAsP | 605-620nm | Amber | 2.0v |

| GaAsP:N | 585-595nm | Yellow | 2.2v |

| AlGaP | 550-570nm | Green | 3.5v |

| SiC | 430-505nm | Blue | 3.6v |

| GaInN | 450nm | White | 4.0v |

Thus, the actual colour of a light emitting diode is determined by the wavelength of the light emitted, which in turn is determined by the actual semiconductor compound used in forming the PN junction during manufacture.

Therefore the colour of the light emitted by an LED is NOT determined by the colouring of the LED’s plastic body although these are slightly coloured to both enhance the light output and to indicate its colour when its not being illuminated by an electrical supply.

Light emitting diodes are available in a wide range of colours with the most common being RED,AMBER, YELLOW and GREEN and are thus widely used as visual indicators and as moving light displays.

Recently developed blue and white coloured LEDs are also available but these tend to be much more expensive than the normal standard colours due to the production costs of mixing together two or more complementary colours at an exact ratio within the semiconductor compound and also by injecting nitrogen atoms into the crystal structure during the doping process.

From the table above we can see that the main P-type dopant used in the manufacture of Light Emitting Diodes is Gallium (Ga, atomic number 31) and that the main N-type dopant used is Arsenic (As, atomic number 33) giving the resulting compound of Gallium Arsenide (GaAs) crystalline structure.

The problem with using Gallium Arsenide on its own as the semiconductor compound is that it radiates large amounts of low brightness infra-red radiation (850nm-940nm approx.) from its junction when a forward current is flowing through it.

The amount of infra-red light it produces is okay for television remote controls but not very useful if we want to use the LED as an indicating light. But by adding Phosphorus (P, atomic number 15), as a third dopant the overall wavelength of the emitted radiation is reduced to below 680nm giving visible red light to the human eye. Further refinements in the doping process of the PN junction have resulted in a range of colours spanning the spectrum of visible light as we have seen above as well as infra-red and ultra-violet wavelengths.

By mixing together a variety of semiconductor, metal and gas compounds the following list of LEDs can be produced.

Types of Light Emitting Diode

- • Gallium Arsenide (GaAs) - infra-red

- • Gallium Arsenide Phosphide (GaAsP) - red to infra-red, orange

- • Aluminium Gallium Arsenide Phosphide (AlGaAsP) - high-brightness red, orange-red, orange, and yellow

- • Gallium Phosphide (GaP) - red, yellow and green

- • Aluminium Gallium Phosphide (AlGaP) - green

- • Gallium Nitride (GaN) - green, emerald green

- • Gallium Indium Nitride (GaInN) - near ultraviolet, bluish-green and blue

- • Silicon Carbide (SiC) - blue as a substrate

- • Zinc Selenide (ZnSe) - blue

- • Aluminium Gallium Nitride (AlGaN) - ultraviolet

Like conventional PN junction diodes, light emitting diodes are current-dependent devices with its forward voltage drop VF, depending on the semiconductor compound (its light colour) and on the forward biased LED current. The point where conduction begins and light is produced is about 1.2V for a standard red LED to about 3.6V for a blue LED.

The exact voltage drop will of course depend on the manufacturer because of the different dopant materials and wavelengths used. The voltage drop across the LED at a particular current value, for example 20mA, will also depend on the initial conduction VF point. As an LED is effectively a diode, its forward current to voltage characteristics curves can be plotted for each diode colour as shown below.

Light Emitting Diodes I-V Characteristics.

Light Emitting Diode (LED) Schematic symbol and I-V Characteristics Curves

showing the different colours available.

showing the different colours available.

Before a light emitting diode can “emit” any form of light it needs a current to flow through it, as it is a current dependant device with their light output intensity being directly proportional to the forward current flowing through the LED.

As the LED is to be connected in a forward bias condition across a power supply it should becurrent limited using a series resistor to protect it from excessive current flow. Never connect an LED directly to a battery or power supply as it will be destroyed almost instantly because too much current will pass through and burn it out.

From the table above we can see that each LED has its own forward voltage drop across the PN junction and this parameter which is determined by the semiconductor material used, is the forward voltage drop for a specified amount of forward conduction current, typically for a forward current of 20mA.

In most cases LEDs are operated from a low voltage DC supply, with a series resistor, RS used to limit the forward current to a safe value from say 5mA for a simple LED indicator to 30mA or more where a high brightness light output is needed.

LED Series Resistance.

The series resistor value RS is calculated by simply using Ohm´s Law, by knowing the required forward current IF of the LED, the supply voltage VS across the combination and the expected forward voltage drop of the LED, VF at the required current level, the current limiting resistor is calculated as:

LED Series Resistor Circuit

Light Emitting Diode Example No1

An amber coloured LED with a forward volt drop of 2 volts is to be connected to a 5.0v stabilised DC power supply. Using the circuit above calculate the value of the series resistor required to limit the forward current to less than 10mA. Also calculate the current flowing through the diode if a 100Ω series resistor is used instead of the calculated first.

1). series resistor required at 10mA.

2). with a 100Ω series resistor.

We remember from the Resistors tutorials, that resistors come in standard preferred values. Our first calculation above shows that to limit the current flowing through the LED to 10mA exactly, we would require a 300Ω resistor. In the E12 series of resistors there is no 300Ω resistor so we would need to choose the next highest value, which is 330Ω. A quick re-calculation shows the new forward current value is now 9.1mA, and this is ok.

Connecting LEDs Together in Series

We can connect LED’s together in series to increase the number required or to increase the light level when used in displays. As with series resistors, LED’s connected in series all have the same forward current, IF flowing through them as just one. As all the LEDs connected in series pass the same current it is generally best if they are all of the same colour or type.

LED’s in Series

Although the LED series chain has the same current flowing through it, the series voltage drop across them needs to be considered when calculating the required resistance of the current limiting resistor, RS. If we assume that each LED has a voltage drop across it when illuminated of 1.2 volts, then the voltage drop across all three will be 3 x 1.2v = 3.6 volts.

If we also assume that the three LEDs are to be illuminated from the same 5 volt logic device or supply with a forward current of about 10mA, the same as above. Then the voltage drop across the resistor, RS and its resistance value will be calculated as:

Again, in the E12 (10% tolerance) series of resistors there is no 140Ω resistor so we would need to choose the next highest value, which is 150Ω.